In How to Operate Concrete Batching Plants Safely (Chapter One) we have mentioned checking rules of concrete batch plants before starting the system, here we are going to discuss matters needing attention after the system starts.

First, the mixer should be started without being fed with any raw materials to check that the rotation direction of mixing tank or blades should be the same as instructed by the arrow outside the tank body. For some concrete batch plants equipped with reverse discharging mixers, workers should make sure there is no shocking, shaking or unusual noise before feeding materials. Second, hoppers should be lifted experimentally to check whether clutches and detents are flexible and stable. Third, during material-feeding process no stretching of head or hands into between a hopper and the frame, or reaching of hands or tools to stir materials in the hoppers. Fourth, when mixers of concrete batch plants are in operation, no staying or walking past under the hoppers while they are lifted. In case of requirement for checking or cleaning of the pit under a hopper, the hopper must be lifted first and locked firmly. Fifth, materials should be fed into mixing tanks of concrete batch plants the tanks are in operation. No new materials should be fed before finished materials have all been discharged. Sixth, the operation state of the plants should be closed observed. The system should be stopped immediately in case of unusual phenomena. Concrete in the mixing tank should be cleared before having it repaired.

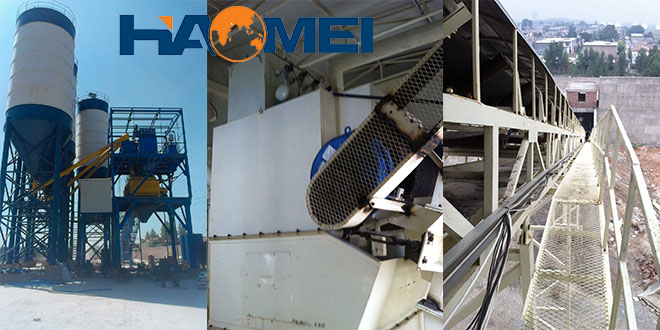

Haomei machinery equipment co. Ltd, a famous manufacturer of quality stationary concrete batch plants, mobile concrete batch plants, concrete mixer, concrete trailer pump, concrete boom pump truck and concrete mixer truck, has decades of manufacturing history and over ten years of exporting experience. Welcome to contact [email protected] for more information..